1. Copper foil adhesion refers to the adhesion force of printed wire and pad on the substrate. The adhesion force is small, and the printed wire and pad are easy to peel off from the substrate. The circuit board factory can check the adhesion of copper foil with adhesive tape, glue the transparent tape to the wire to be detected, remove bubbles, and then quickly pull off the tape with a target of 90° with the printed circuit board. If the wire is intact, the copper foil adhesion of the printed circuit board will pass the footnote.

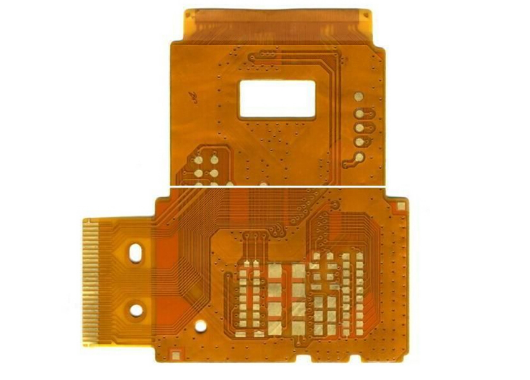

2. The circuit board factory quality inspection includes surface brightness, clear like the silk screen, welding plate is rounded and whether welding hollow in the center of the pad, photo reproduction way is used to make the film cover on the already processed printed circuit board, determination of the edge of the printed circuit board size, the width and the appearance of the wire is in the requirements within the boundaries.

3. Pad solderability is an important indicator of printed circuit board, focusing on measuring the wetting strength of solder to printed pad, which is divided into wetting, semi-wetting and non-wetting three indicators.

4. Electrical function inspection focuses on the insulation and connectivity of FPC soft board, and connectivity can be measured by optical board tester. Insulation inspection focus on measuring insulation resistance, circuit board factory may choose two or more closely spaced wires, first measuring insulation resistance, and then humidification heating time and restore to room temperature after measurement again.

The above is to detect the quality of FPC soft board, I hope to help you.

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA