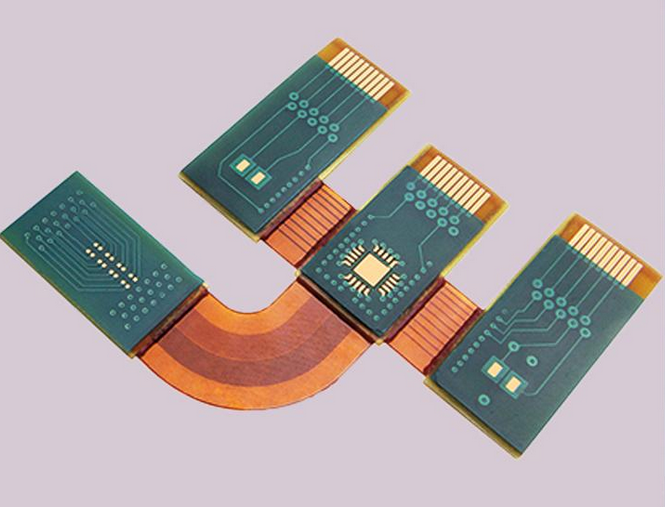

FPC can be divided into single panel, double panel, layered board, multi-layer layered board, soft and hard combination board, etc. The FPC on the two layers are connected to each layer through the through-hole. So what are the materials of FPC screen layout? Here is a brief overview:

1. Base: PI polyimide is generally used as the material, but also PET polyester. The thickness is 12.5, 25, 50, 75, 125um. 12.5 and 25um are commonly used. PI is superior to PET in various properties.

2. Copper foil layer: calendered copper and electrolytic copper thickness of 18, 35, 75um. Because the calendered copper has better mechanical properties than electrolytic copper, the calendered copper is preferred in FPC pressing screen arrangement which requires frequent bending. The copper foil thickness of the main screen FPC is generally 18um.

3. Covering layer: the material is the same as the base, covering on the copper foil, which plays the role of insulation, welding resistance and protection. The usual thickness is 12.5um.

4. Adhesive: the adhesive to each layer.

5. Reinforcement plate and reinforcement film: for the plugged FPC, in order to match with the standard socket, a reinforcement plate should be added on the back of the contact surface, and the material can be PI, PET and FR4; Common PET. The thickness of the contact bit of the reinforcement plate is determined according to the requirements of the socket, generally 0.3, 0.2 or 0.12mm. For the FPC terminal that needs to be bonded to the LCD, a reinforced film should be designed on the back of the contact surface, and 12.5um PI material should be used.

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA