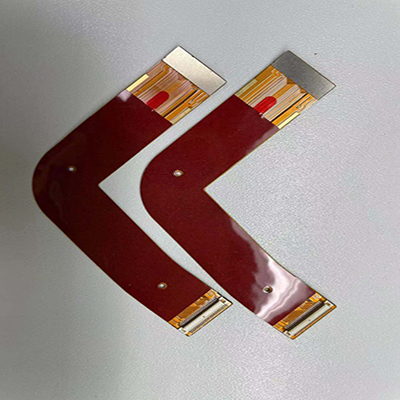

Flexible Printed Circuit Board (FPC) refers to the Flexible Printed Circuit board (FPC), also known as the Flexible Printed Circuit board, Flexible Printed Circuit board, or soft board. The flexible circuit board has the advantages of high wiring density, light weight and thin thickness. Widely used in mobile phones. Laptop. PDA. Digital camera. LCM and many other products. In recent years, WITH the rapid development of PCB manufacturing technology, the industry has put forward higher requirements for flexible PCB. Precision PITCH is the main breakthrough direction of flexible PCB in the future. The stability of the size, exquisite also caused the rise of the cost of flexible circuit board, how to control the contradiction of the two, in the production process of flexible circuit board material expansion and contraction control as the main breakthrough. Here's how to control it. The main points of control are briefly explained to you.

First, design

1. Circuit: due to the expansion of the flexible circuit board due to temperature and pressure when crimping, the expansion rate of the crimping finger should be considered in the initial design of the circuit, and the pre-compensation processing should be carried out;

2. Layout: the design of flexible circuit board products as much as possible symmetrical distribution in the whole layout, the minimum interval between each two P-CS products shall be more than 2 MM, the copper-free part and the hole intensive part shall be staggered as far as possible, these two parts are two important aspects caused by the material expansion and contraction in the subsequent manufacturing process.

3. Material selection: the plastic covering film can not be too thin than the thickness of the copper foil, so as not to cause the deformation of the product when the rubber filling is insufficient, the thickness of the rubber and whether the uniform distribution, is the culprit of the flexible circuit board material expansion and contraction.

4. Process design side: the covering film of the flexible circuit board should cover all copper foil parts as far as possible, and it is not recommended to stick the covering film to avoid uneven force when pressing. The PI reinforcing bonding surface glue on 5MIL should not be too large, if it cannot be avoided, the covering film should be pressed and baked before PI reinforcing bonding.

Two, material storage

I believe that the importance of material storage need not say more, it is necessary to store in strict accordance with the conditions provided by the material supplier, the cold storage of the cold storage, not careless.

Three, manufacturing

1. Drilling: it is best to add baking before drilling the flexible circuit board to reduce the expansion and contraction of the substrate due to the high moisture content in the substrate during subsequent processing.

2. Electroplating: the flexible circuit board should be made of short side plywood, which can reduce the deformation caused by the water stress caused by the swing. When electroplating, the pendulum kinetic energy reduces the flow on the plate, so as not to cause adverse effects on the plate electroplating.

3. Pressing: the traditional press of flexible circuit board is up and down more than the fast press. The traditional press is constant temperature curing, and the fast press is hot curing, so the change of the control glue of the transmission press is stable, of course, the laminating plate is also a very important part.

4. Baking: flexible circuit board for fast pressure products, baking is not often important part, baking conditions must be reached to make the glue completely solidified, otherwise in the subsequent production or use after infinite; The baking temperature curve is first gradually rising to the temperature at which the glue is completely melted, and then continuing at this temperature until the glue is completely solidified, and then gradually decreasing the temperature and cooling.

5. During the production process, try to maintain the stability of temperature and humidity in all stations. Special attention should be paid to the storage conditions of the products when transferring between stations, especially when the products need to be sent out.

4. Packaging

Of course, the completion of flexible circuit board products is not to say that all is well. It is necessary to ensure that customers do not have any problems in the subsequent use. In terms of packaging, it is best to bake first, dry the moisture absorbed by the base material in the manufacturing process, and then use true empty packaging, and guide customers how to save.

Therefore, to ensure the stability of the quality of flexible circuit board products, materials preservation, process control, packaging and customer use must be carried out in strict accordance with specific requirements.

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA