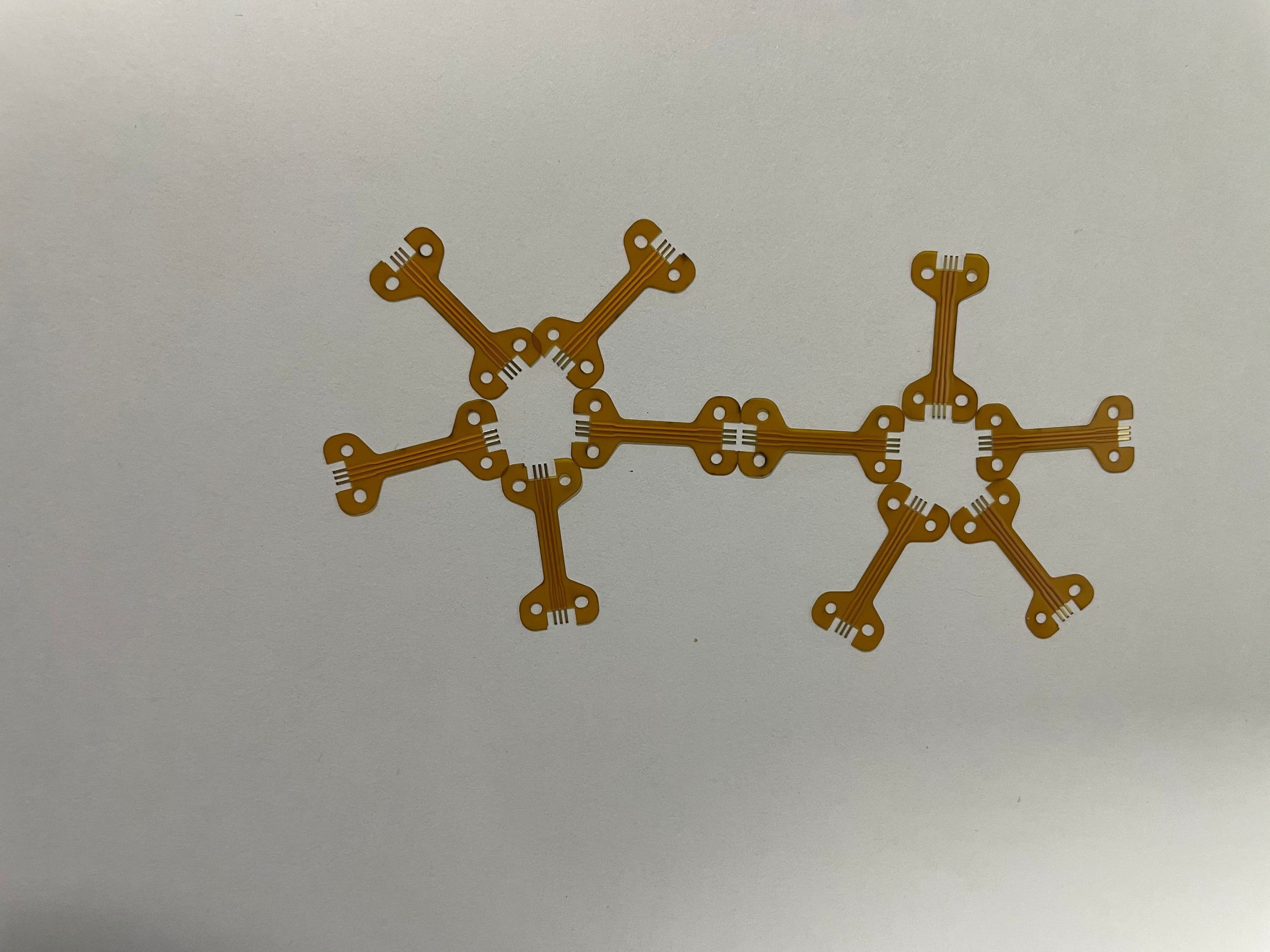

FPC hollow out board is also known as flexible circuit board. It is a printed circuit with high reliability and excellent flexibility. This kind of hollow plate circuit can be bent at will, folding light weight, small volume, good heat dissipation, easy installation and other advantages in the electronics and communication industry has been increasingly attached importance to and widely used.

The production process of FPC hollow out board of flexible circuit board can be summarized as the following technological process:

1 cutting: flexible circuit board FPC according to the required size of the base material into the initial cutting, size is required and its surface can not have creases, stains and so on.

2.CNC drilling: flexible circuit board FPC according to the design drawings of the aperture or pattern of the size and shape of the board into high-speed drilling.

3 copper plating: flexible circuit board FPC with chemical copper precipitation principle on the surface of the substrate and copper hole surface plated with a thin layer of copper layer, and check its thickness, the requirements of the copper plating to be uniform and smooth. And the appropriate chemical washing, will be easy to remove the surface.

4. Apply dry film.

5. Exposure on both sides: FPC of flexible circuit board places the FPC engraved hollow board of semi-finished flexible circuit board under certain lighting conditions to detect whether there is a pinhole break and other conditions.

6. Development: Display the image of the negative.

7. Etching: FPC of flexible circuit board can remove oxides and impurities on the surface of hollow plate, and enhance the adhesion ability of copper and surface.

8. Film removal and chemical cleaning: the flexible circuit board FPC will remove more than part of the dry film attached.

9. Paste protective film: the protective layer on the surface of FPC hollow out board of flexible circuit board.

10 lamination: the flexible circuit board FPC makes the film stick more firmly on the surface of the FPC hollow plate.

11 plating lead or nickel gold: some need to increase the special function of the flexible circuit board FPC hollow plate need to be plated with this metal to achieve.

12. Cutting and punching shape: to deal with the appearance of FPC hollow out board of flexible circuit board, whether there are burr, pull and other bad appearance phenomenon.

13. Detection: the FPC hollow out board of the flexible circuit board obtained by the system is tested and compared with the standard sample, and its appearance and performance are consistent.

It can be seen that the production of FPC hollow out board of flexible circuit board needs to go through many complex technological processes, and the requirements of each technological process are very high and play a very important role in its molding. Of course, with the continuous progress and maturity of technology, FPC flexible circuit board in the future many processes, can be enough to achieve a complete or complete automatic production.

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA