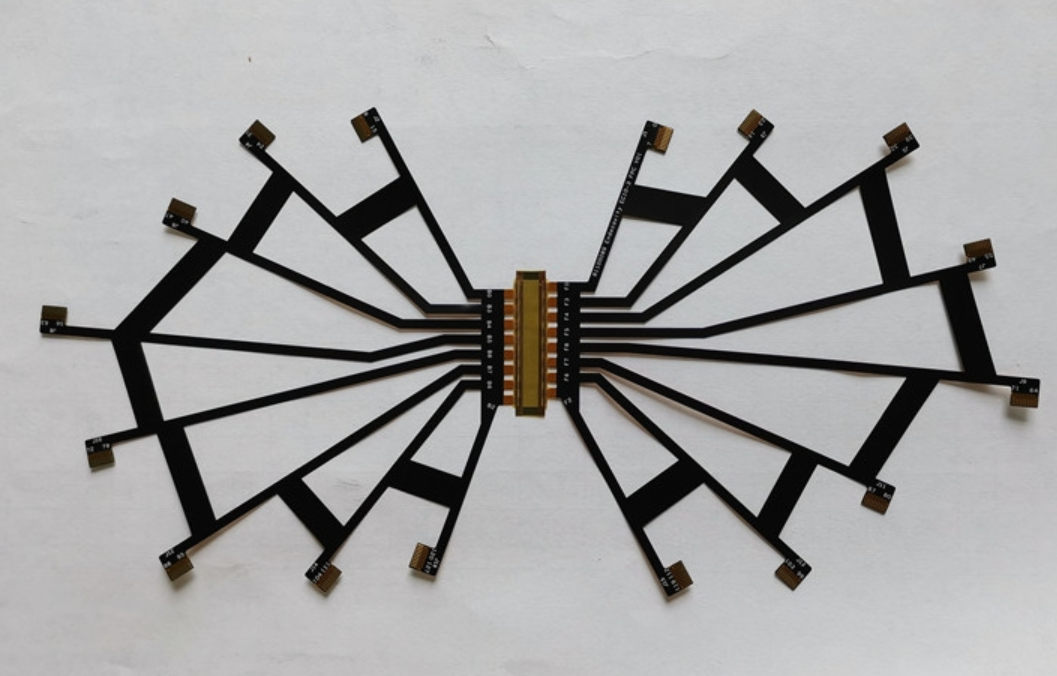

The working principle of the circuit board: it is to use the plate insulation material to separate the copper foil conductive layer on the surface, so that the current flows along the pre-designed route in various components to complete functions such as work, amplification, attenuation, modulation, demodulation, coding and so on. On a basic PCB, the parts are concentrated on one side and the wires are concentrated on the other. Because the wire appears on only one side, the PCB is called a single-sided FPC flexible board. Multilayer FPC flexible circuit board, multilayer with wires, only between the two layers of the appropriate circuit connection, the bridge between the circuit is called the guide hole (VIA). The basic circuit board design process can be divided into the following four steps:

V automobile brake lamp FPC flexible circuit board aluminum substrate is a kind of metal base copper clad plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are respectively circuit layer (copper foil), insulation layer and metal base. Common in LED lighting products V car brake lights FPC flexible circuit board. There are positive and negative sides, the white side is welded LED pin, the other side is aluminum color, generally daub heat conduction paste and heat conduction part contact. There are ceramic substrates and so on. Advantages of aluminum substrate :1. More suitable for SMT process 2. RoHs requirements 3. The heat dissipation has been effectively dealt with, so as to reduce the operating temperature of the module, prolong the service life and improve the reliability; V Automobile brake lamp FPC flexible circuit board 6, aluminum substrate pad and line scratch and crush bubble are not in conformity with the requirements of the products. Aluminum substrate surface color yellow do not receive. 8. Line, pad and engineering drawings, samples consistent, line wireless large, thin damage phenomenon, pad no ink, no damage and too large or too small phenomenon V automotive brake light soft plate (1) circuit schematic design - circuit schematic design is mainly using ProtelDXP schematic editor to draw schematic diagram. (2) generate reports - network statement that shows the links of all components in the circuit principle and relationship of the report, it is connected to circuit schematic design and circuit board design of bridge and link, through the network statements circuit schematic diagram, can quickly find the components, the relation between which provide convenience for the back of the PCB design. A. Aluminum substrate technical requirements, the main technical requirements are: size requirements, including plate size and deviation, thickness and deviation, verticality and warpage; Appearance, including cracks, scratches, burrs and delamination, aluminum oxide film requirements; Performance, including peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

V automotive brake lights FPC flexible circuit board 2. Double layers FPC FPC flexible LCD double soft plate structure: when the circuit of the circuit is too complex, single board to wiring or in need of copper foil for earth shield, you need to choose double plate laminated V automotive brake lights even FPC flexible LCD glass fiber board and aluminum substrate PCB there are three differences between: A. In terms of price, the important components of LED fluorescent tubes are: circuit board,LED chip and drive power supply. Common circuit boards come in two types: aluminum and fiberglass. Comparing the price of fiberglass with that of aluminum, fiberglass will be much cheaper, but the performance of aluminum will be better than fiberglass. B. Technology: According to different materials and manufacturing process, fiberglass can be divided into three types: double-sided copper foil fiberglass, perforated copper foil fiberglass and single-sided copper foil fiberglass. Of course, the price of fiberglass panels made of different materials will vary. Fiberglass panels are made of different materials and technologies at different prices. LED fluorescent tubes and fiberglass do not dissipate heat as well as LED fluorescent tubes with aluminum-based panels. The most typical difference between laminates and single laminates is the addition of a perforation structure to connect the layers of copper foil. General substrate + transparent adhesive + copper foil the first processing process is to make holes. First in the base material and copper foil drilling, after cleaning coated with a certain thickness of copper, through the hole is ready. The subsequent production process is almost the same as that of single-layer FPC flexible circuit board.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA