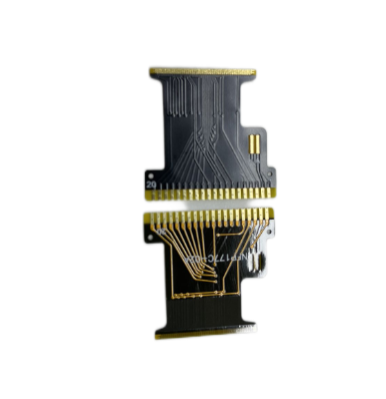

Common defects and solutions on the surface of FPC wiring board

1. Bubbles are formed after side expansion of FPC line board or single line

Main reason: air bubbles occur between two or more lines, mainly because the line spacing is narrow, the line is too high, so that the solder resist can not be printed on the substrate during screen printing, resulting in air or moisture between the solder and the substrate. Gas thermal expansion during curing and exposure is mainly caused by overheight lines. When the blade is in contact with the line, the included Angle between the scraper and the wire increases, so that the solder resist can not be printed to the root of the line, so that there is gas between the root of the weld and the weld resist layer, and bubbles are generated after heating.

Solution: when screen printing, it is necessary to check whether screen material is completely printed on the substrate and the side wall of the line, and strictly control the current when electroplating.

2, FPC line plate hole, with resistance welding and graphic pinhole

The main reason is: the flexible circuit board does not print paper in time in the screen printing process, resulting in excessive accumulation of residual ink in the screen, the residual ink is sent into the hole under the pressure of the scraper, and the number of screen is too small, it will also cause welding resistance in the hole. There is dirt on the photographic baseplate, which causes the FPC wiring board to fail to see light during exposure, resulting in pinholes in the pattern.

Solution: timely use of high mesh printing paper and screen, exposure often check the cleanliness of the photo.

3. The copper foil line appears black under the resistance welding layer of FPC wiring plate.

Main cause: The flexible circuit board is not dried after wiping, and the surface of the printed circuit board is splashed by liquid or manual forming before printing resistance welding.

Solution: Screen printing on both sides of the printed board copper foil oxidation phenomenon.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA