Now the high thermal conductivity is usually ceramic, copper, etc., but because of considering the cost of doubt, most of the aluminum substrate on the market now, the corresponding thermal conductivity of aluminum substrate is the parameter we care about, the higher the thermal conductivity is

Is one of the symbols of better function. Aluminum substrate is a common metal base copper-clad aluminum substrate, which has good thermal conductivity, electrical insulation and machining function. The thermal conductivity of aluminum substrate is usually 1.0,

1.5, 2.0, the specific situation still depends on the demand for goods.

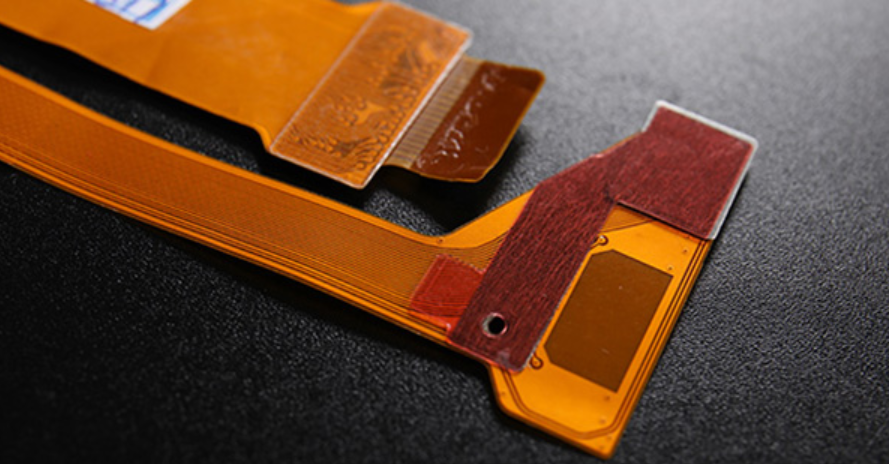

The aluminum substrate of the flexible circuit board of the foot sensor is a metal copper-clad plate with good heat dissipation function. Generally, the single panel is composed of three layers, which are the circuit layer (copper foil), the insulation layer and the metal base. In the LED

Flexible circuit board of foot sensor for lighting products. There are positive and negative sides, the white side is welded LED pin, the other side is aluminum color, generally daub heat conduction paste and heat conduction part contact. There are ceramic substrates and so on

And so on. Advantages of aluminum substrate :1. More suitable for SMT process; 2. 3. The heat dissipation has been effectively dealt with, thus reducing the operating temperature of the module, prolonging the service life and improving the reliability. A review of plantar sensor FPC in China

External discussion on the development trend of future printed board manufacturing technology is basically the same, that is, to high density, high precision, fine aperture, fine wire, fine spacing plantar sensor FPC, PCB board is generally copper substrate, which is also divided into

There are obvious differences between single panel and double panel. Aluminum plate is the main material of aluminum substrate, while COPPER is the main material of PCB board. Aluminum substrate because of its SPECIAL PP material. Heat dissipation is better. The price also

More expensive. Compared with THE two in terms of heat dissipation, the performance of aluminum substrate in heat dissipation is more superior to that of PCB board, and its thermal conductivity is also different. Aluminum substrate is a kind of PCB, and the price of aluminum substrate is more expensive, high reliable and more

Layered, high-speed transmission, light weight, thin direction development, in production at the same time to improve productivity, reduce costs, reduce pollution, adapt to the variety, small batch production direction development. The technical development level of printed circuit is generally

The line width, aperture, and thickness/aperture ratio on the printed board are represented by.

3. To begin welding all pins, add solder to the tip of the soldering iron and apply flux to all pins to keep them wet. The flexible circuit board contacts the end of each pin of the chip with the soldering iron tip

5. Fill: Copper pack for ground wire network, can reduce impedance. 6. Electrical boundary: used to determine the size of the circuit board. All components on the circuit board must not exceed this boundary. circuit

Board names are: circuit board, PCB board, aluminum substrate, HF board, thick copper board, impedance board, PCB, ultra thin circuit board, ultra thin circuit board, printing (copper etching technology) circuit board and so on. The circuit board makes the circuit miniaturized and intuitive

It plays an important role in the batch production of fixed circuit and the optimization of electric appliance layout. Circuit board can be called PrintedCircuitBoard or PrintedCircuitBoard, English name is (PrintedCircuitBoard) PCB, (

FlexiblePrintedCircuitboard) [1] in FPC circuit board (FPC circuit board, also known as flexible PCB flexible circuit board based on polyimide or polyester film base material made of a kind of with high reliability, flexible printing

Road plate. During welding, the tip of the soldering iron should be kept parallel with the soldering pin to prevent the flexible circuit board of the sole sensor from being overlapped due to excessive soldering tin. 4. After soldering all the pins, wet them with flux to clean the solder. The need to

Suck off excess solder to eliminate any short circuits and lap joints. Finally, use tweezers to check for soldering. When finished, remove flux from the circuit board, dip a stiff brush in alcohol and wipe it carefully in the direction of the pins until soldering

The agent disappears.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA