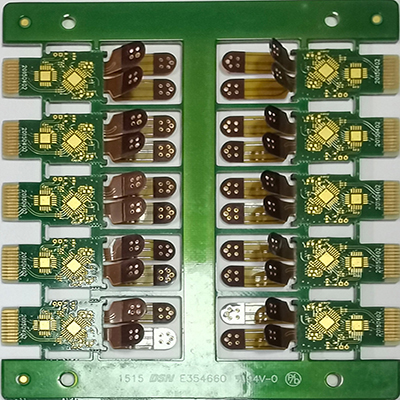

With the diversification and miniaturization of use, the flexible circuit board in electronic equipment requires high density flexible circuit board circuit, but also requires high performance in the qualitative sense. Nearest flexible circuit board circuit density

Change. Using the reduction method (etching) can form a conductor pitch of less than 30um single-sided circuit, conductor pitch of less than 50um double-sided PCB circuit has also been practical. The connection

The conduction aperture between the conductor layers of double-sided circuits or multi-layer circuits is also getting smaller and smaller. Now the conduction aperture of holes below 100um has reached the mass production scale.

Possible manufacturing range of high density flexible circuit board based on manufacturing technology standpoint. According to circuit pitch and through-hole aperture, high-density flexible CIRCUIT board circuit can be roughly divided into three types:

(1) Traditional flexible circuit board.

(2) High-density flexible circuit board.

(3) Ultra-high density flexible circuit board.

In traditional flexible circuit board reduction methods, FPC with a pitch of 150um and a through-hole aperture of 15um has been mass-produced. Due to the improvement of the material or the processing device, it can be added even in the reduction method

30um line pitch. In addition, due to the introduction of CO2 laser or chemical etching process, can achieve 50um aperture through hole mass production processing, most of the current mass production

High density FPC is processed using these technologies.

However, if the pitch is less than 25um and the through-hole diameter is less than 50um, it is difficult to improve the pass rate even if the traditional technology is improved, and new process or new material must be introduced. now

There are various processing methods, but the half addition method using electroforming (sputtering) technology is the most suitable method, not only the basic process is different, but also the use of materials and auxiliary materials

The material is also different.

On the other hand, the progress of FPC joint technology requires FPC to have higher reliability performance. With the high density of circuit, the performance of flexible circuit board has put forward the requirements of diversification and high performance.

These performance requirements are largely dependent on the circuit processing technology or materials used.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA