Analysis of two main reasons of flexible circuit board fracture

To know these two reasons also have to be from professional design analysis, hinge space to leave enough, flexible circuit board FPC can not be too hard.

1. Flexible circuit board is too short.

2. The material is too hard, and the soft material may be better. 100,000 times of folding is not a problem.

There is also a point, the flexible circuit board broken is the initial problem, this problem I personally think is not very difficult, the most fatal is the flexible circuit board, eliminate the interference of the flexible circuit board and the hole, you have a good way to the flexible circuit board sound? There are several kinds of problems caused by flexible circuit board: LCD does not display and flip tone caused by fracture; Length is too short for fracture, mostly in the design, in addition to wear FPC hole clearance of structure design is not reasonable cause, clamshell different sounds are scratching, flexible circuit board and the external shell wall contact in the flexible circuit board to repeatedly try several times to design reach the designated position, had better use the transparent joke, or to cut open a joke, more observation, then make design improvements.

Of course, some manufacturers began to make samples when there is no problem, and then there is a problem in mass production, we must see if it is the problem of the material

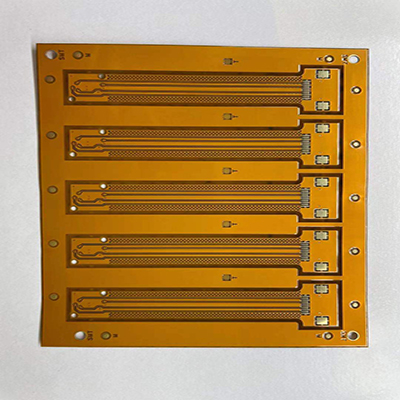

(A) First analyze the picture of the broken flexible circuit board, as can be seen:

1. The fault is the electromagnetic shielding layer of the outer layer of the flexible circuit board

2. It can be seen from the picture that this layer is folded from the back of the product in the swing area, so it is judged that this layer is made separately and then attached to the line product

(II) Prediction of fracture causes:

1. The shielding layer is solid copper with great hardness, which increases the possibility of fracture in the process of swaying.

2. The shielding layer is separately attached to the row line, which is not a close whole with the row line product. During the swing process, it will deviate from the original set bending direction, which may lead to excessive stress concentration and fracture.

(Therefore, the material problem of flexible circuit board mentioned by LBMouse is excluded as the direct cause of fracture. In addition, structural problems are not discussed because there is no corresponding information.)

(III) Suggestions:

1. Wrap adhesive tape around the fracture and bind the flexible circuit board line to increase its tightness with the line.

2. Change the copper surface of shielding layer to grid to reduce hardness.

1. Long-term recommendations:

For the shielding layer of the flexible circuit board swing area, the use of printed or coated conductor production method, or the bonding of conductive cloth dedicated to the electromagnetic shielding of the line, will completely avoid the problem of shielding fracture, and the cost will not increase.

The above is my personal advice, I do not know what opinion you prawn.

The flexible circuit board can be designed to prevent a tear line, Korean mobile phones have tear line. Last time our company's mobile phone was transferred to domestic production, domestic manufacturers began to have problems, and then there was no problem when we added the tear line. DOME also has a protective coating to protect against moisture and dust!

It should be possible to change the copper layer of FPC to copper net and increase the deflection of FPC. However, it is suggested that we have to do this as far as binding is concerned. For the fracture of this picture, I personally think that the attention is caused by pulling, that is, the row line is too short, and the row hole problem, mainly the mechanism of the rubber shell. Now we have used silver pulp printing, which can make the line thinner, and the effect is also good, 100,000 times OK! ]

This basket empty structure, refer to the bending of the mobile phone motherboard.

This is caused by twisting and pulling during flipping. The row lines at b-B in the figure (right) should be moved to the middle to lengthen the length of torsional deformation to reduce the possibility of fracture.

Flexible circuit board shielding is now a lot of useful aluminum foil, clamshell will be better;

Flexible circuit board design should I think the most main is to reduce the stress concentration, rounded corners is must as far as possible big, many cases are in the fillet fracture of the FPC, more rounded corners will be improved substantially, the ends of the shaft do not have apparent stress produced (like about connectors don't stand too close to the people in rotor lead parts, at the ends of the wire bonding layer can produce a large torque)

The flexible circuit board also has its own torsional force, the axial length of the axial part of the longer will weaken its own torsional force, but too long will have obvious patting sound between layers;

The supplier of flexible circuit board is also a very important link. There are electrolytic copper and calendered copper on the copper line. The life of electrolytic copper is relatively low, which may affect the test;

The length simulation of the flexible circuit board is very important. It is good to analyze the failed parts in one step as far as possible.

In fact, the life of the flexible circuit board is also related to the shell structure. Because of the frequent need to move, and the limited space in the housing, the line will inevitably contact with the hard housing. The clamshell is not so obvious. The canopy is not.

Quality is inseparable from price. But the single value of the flexible circuit board is relatively cheap, but its onboard original device is not cheap, and if the warranty period is damaged, the warranty cost is much higher than the value of the FPC

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA