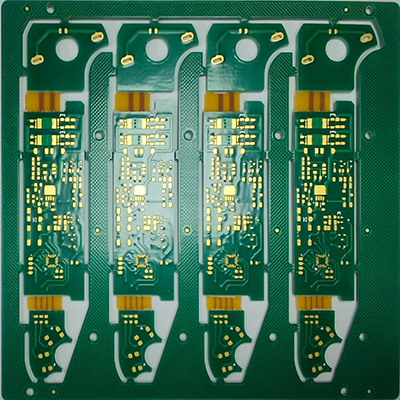

There are many classification methods of flexible circuit board products. According to the number of laminating layers of flexible circuit board, it can be divided into single panel, double panel, multi-layer board and soft and hard combination board. As a common type of circuit board, the market share of flexible circuit board is rising with the development of electronic products to miniaturization and portability. However, the flexible circuit board may appear in the process of processing, loading, mounting and other production defects such as circuit break, short circuit, line width inconsistent. In view of this, this paper mainly analyzes the defect detection method of flexible circuit board.

Different production technology makes it has many unique characteristics:

(1) The assembly density of flexible circuit board is high, reducing the connection between parts;

(2) The flexible circuit board is light in weight and thin in thickness, which can effectively reduce the weight of the product and is convenient to carry;

(3) The flexible circuit board can be folded and bent arbitrarily.

The flexible circuit board has the advantages of good reliability, strong heat dissipation, easy installation, low comprehensive cost, and provides convenience for the high integration and high performance of electronic products.

There are many classification methods of flexible circuit board products. According to the number of laminating layers of flexible circuit board, it can be divided into single panel, double panel, multi-layer board and soft and hard combination board.

Development status of defect detection technology of flexible circuit board

The existing defect detection algorithms of flexible circuit board are mostly derived from PCB detection algorithm. However, due to the limitation of its uniqueness, the defect accuracy of flexible circuit board is required to be higher, the detection sample size is larger, and the image of the sample is easy to be deformed. Therefore, the defect detection algorithm for PCB cannot be directly applied to the detection algorithm of flexible circuit board. It is necessary to develop a suitable detection algorithm according to the actual circuit characteristics of the flexible circuit board.

China metrology institute of the traditional problem of slow speed and low accuracy of template matching algorithm, the proposed flexible circuit board line defects can be divided into two categories, global and local defect, eight connected domain area method combined with global histogram matching method to capture image defects, on the basis of projection matching and correlation coefficient method is used to identify local defect of the image. This method is faster and more accurate than traditional detection algorithms, but the classification of related defect categories is not detailed enough.

Analysis of defect detection methods of flexible circuit board

For the global template matching problem, the local template matching method is considered to implement FPC defect detection. Considering the contour based template matching method, the template should have significant contour characteristics. Although the conventional lines on the flexible circuit board have regular trend, they have no significant shape characteristics. Moreover, the conventional lines are distributed in the whole image, and the large template matching time is too slow, which is not conducive to line detection.

Special-shaped circuit belongs to the irregular shape on the flexible circuit board, generally including LED lights, S-shaped circles, etc. Due to the shape of peripherals, the wiring is generally related to the pattern structure of the flexible circuit board to be inspected. For this kind of line, the template matching method is considered to implement detection: firstly, the position and pose of each irregular line on the whole FPC are located by rough step of template matching method, and the contour of irregular line is obtained. Then defect detection was carried out based on morphology theory.

Flexible circuit board defect detection method guide

(1) Load the data information related to the registration template, including the registration template area and profile information.

(2) Using the regional information carried by the registered template, locate the template search space, and search the template instance in the search image based on the metric principle of normalized Correlation number (NCC).

(3) Cut the irregular area. The size of the special-shaped region is obtained by taking the smallest enclosing rectangle of the shape template instance. Since the shape template is a rectangular region, the region obtained by the smallest enclosing rectangle is the matched special-shaped region. Arbitrary template matching cannot make two images perfectly aligned in space, there is a match within a permissible range. Due to the reduction of the space range, the matching accuracy of the shape template is improved. The overall matching error is about 1/5 line width (3 pixels), which is within the allowable range of defect determination.

(4) Considering the precision error of shape matching, before the difference between the standard template image and the image of the irregular region is calculated directly, corrosion operation is carried out on the irregular region by small size structural elements to remove the influence of boundary difference. When there are defects in the image, the corrosion operation at this size cannot completely corrode the defective line, so the final judgment result is not affected.

(5) Regional difference set calculation is carried out between the template image and the irregular region to obtain the difference region of the two. When there is no defect, the difference is 0. When there is a defect, the region difference set returns a binary image which is not 0.

(6) Mark the connected domain of the difference image to segment different defect blocks;

(7) Calculate the area of each connected domain, and take the geometric size center of the largest defect block as the center of the irregular region to output the defect information.

The defect detection method of flexible circuit board is studied from global and local scope, and experimental conclusions are drawn:

(1) Due to the imaging deformation of the flexible circuit board, the template matching circuit based on the global scope is misaligned, and the defect information on the image cannot be correctly located.

(2) Based on template matching in local scope, firstly, the line regions with significant shape characteristics compared with conventional lines on the FPC board are cut out and taken as the template; Instance detection is performed near the corresponding template area on the search image to compress the search space. Then the line defect information is detected based on morphology theory.

In short, the circuit board as the most basic component of electronic circuit, greatly affects the quality of the entire electronic products. Therefore, how to implement precision of circuit board defect detection is an important link of the product quality assurance, and most domestic enterprises commonly rely on artificial visual to the flexible circuit board defect detection, high cost and low efficiency, and because there is no relative standard quality inspection standards, staff by reason of subjective consciousness or visual fatigue prone to leak and mistakenly identified; Due to the limitations of equipment price, technical support and after-sales service, the excellent foreign testing equipment introduced by some enterprises is difficult to adapt to the low cost and mass production needs of modern technology. Therefore, it is urgent to develop a set of fast and efficient automatic detection system of flexible circuit board defects to meet the needs of the domestic market.

Polly peak circuit board as a professional flexible circuit board manufacturers, we are in the direction of the digital camera, car satellite positioning device, liquid crystal TV, notebook computer, medical instrument, intelligent robot, mobile phone and so on are involved in the communication field and research and development, thank you very much for support of numerous customers to polly peak, willing to work with us hand in hand advance together, welcome more customers come to discuss cooperation.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA