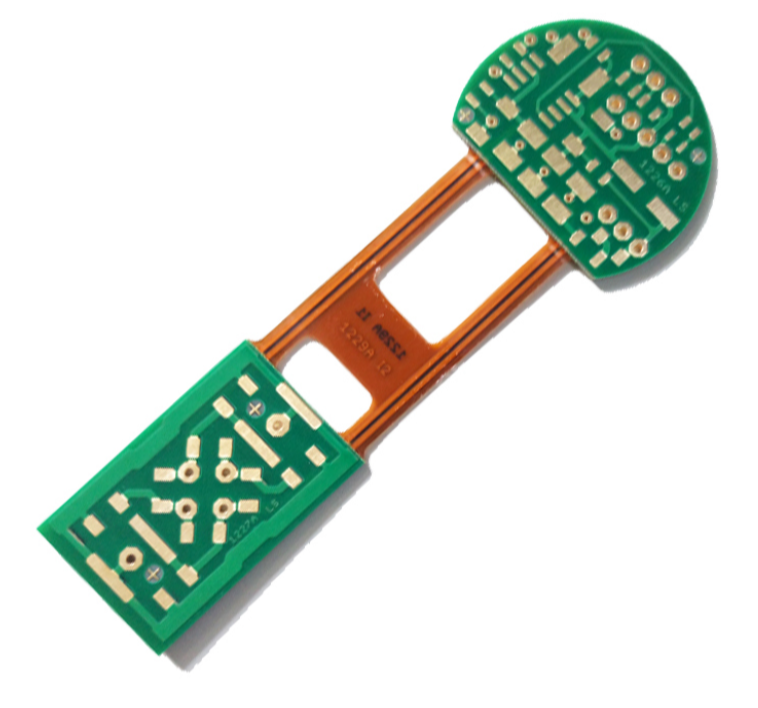

1. Double-sided flexible circuit board structure: flexible circuit board double-sided soft board structure: double-sided flexible circuit board has welding pads on both sides, mainly used for connection with other circuit boards. Although its structure is similar to that of single-layer board, the manufacturing process is very different. Its raw materials are copper foil, protective film + transparent glue. First, drill holes on the protective film according to the location requirements of the pad, and then paste the copper foil. After etching out the pad and lead, paste another protective film with a well drilled hole. Double-sided LED flame lamp flexible circuit board and circuit board no difference, essentially the same. The circuit board is only a design and production of a good substrate, circuit board refers to the circuit board has been installed with each component of the double-sided LED flame lamp flexible circuit board

2. The working principle of the circuit board: it is to use the plate insulation material to separate the copper foil conductive layer on the surface, so that the current flows along the pre-designed route in various components to complete such work. Amplification. Attenuation. Modulation. Demodulation. Coding and other functions. On a basic PCB, the parts are concentrated on one side and the wires are concentrated on the other. Because the wires only appear on one side, the PCB is called a single panel. A multilayer board, with multiple layers of wires, requires a proper circuit connection between the two layers, and the bridge between the circuits is called the guide hole (VIA). The basic circuit board design process can be divided into the following four steps: circuit board name: circuit board,PCB board, aluminum substrate, high-frequency board,PCB, ultra-thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board and so on. The circuit board makes the circuit miniaturized and intuitive, which plays an important role in the batch production of fixed circuit and the optimization of electric appliance layout.

3. 7.3m adhesive paper for flexible circuit board of double-sided LED flame lamp - mainly used for FR4 with thickness of 0.4mm and above to paste flexible circuit board, and assemble and fix flexible circuit board with customer products; The use of flexible CIRCUIT board auxiliary materials, ultimately according to the customer's use environment and functional requirements to determine the double-sided LED flame lamp flexible circuit board

4. The thermal conductivity test method and test results do not match, and there is a certain difference between the thermal conductivity of the dielectric layer and the finished thermal conductivity of the aluminum substrate.

5. Aluminum base copper clad plate material specifications are not unified. CPCA industry standards, national standards, international standards and so on.

6. The thickness of copper foil is not up to standard, which will lead to some phenomena such as burning circuit and exploding power supply.

7. More and more PCB manufacturers, copycat defective spoiler, jerry-built, shoddy, steal for a pillar. The classification of FPC circuit board is classified according to its medium and structure, which is sorted as follows: 1, single-layer flexible circuit board structure flexible circuit board this structure of the flexible circuit board is the most simple structure of the flexible board. This is usually the base material + transparent adhesive + copper foil is a set of bought raw materials, of course, protective film + transparent adhesive is another kind of bought raw materials.

1. Shorten the connection between high frequency components and reduce EMI interference. 2. Components with large weight (such as more than 20g) should be fixed with support and then welded. 3. Heat dissipation of heating elements should be considered to prevent large δ T surface defects and rework, and heat sensitive elements should be kept away from the heating source double-sided LED flame lamp flexible plate. 4. Filling: used for copper coating of ground wire network, which can reduce impedance. 5. Electrical boundary: used to determine the size of the circuit board, all components on the circuit board must not exceed this boundary. Circuit board names are: circuit board, PCB board, aluminum substrate, hf board, thick copper board, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board and so on. The circuit board makes the circuit miniaturized and intuitive, which plays an important role in the batch production of fixed circuit and the optimization of electric appliance layout. Circuit boards may be called printed circuit boards or printed circuit boards, English name is (PrintedCircuitBoard) PCB, FPC PCB (FlexiblePrintedCircuitboard) [1] (FPC circuit board, also known as flexible PCB flexible circuit board is made of polyimide or polyester film as the backing material with a high reliability, Flexible printed circuit board. 6. The arrangement of components as parallel as possible, so that not only beautiful and easy to weld, suitable for mass production. Circuit board design is 4∶3 rectangular (preferred). Do not mutate wire widths to avoid discontinuities in wiring. When the circuit board is heated for a long time, copper foil is easy to expand and fall off. Therefore, large copper foil should be avoided.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA