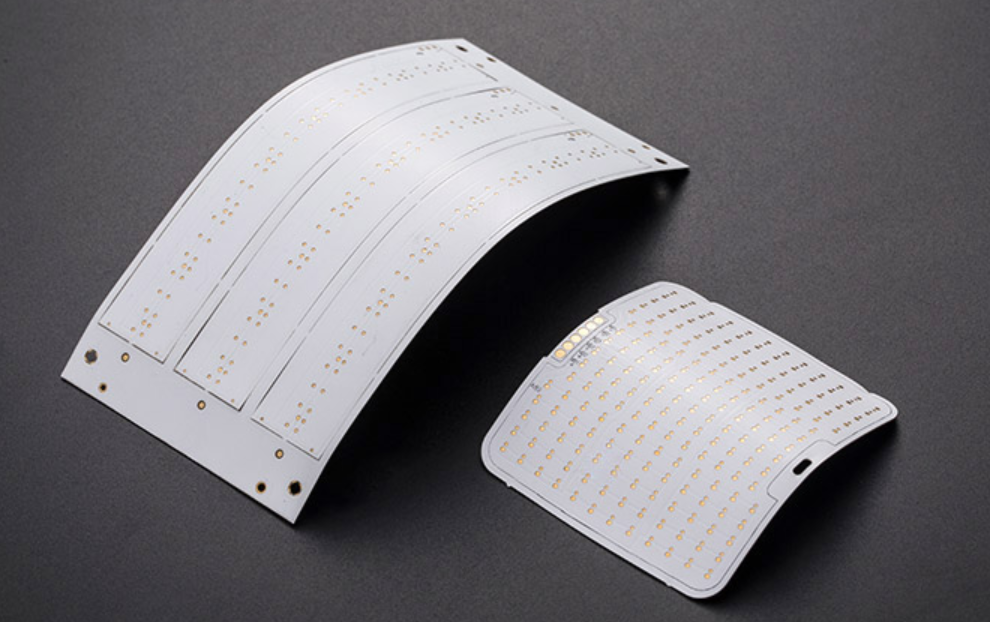

Circuit board (PCB) alias: circuit board, PCB board, aluminum substrate, HF board, ultra-thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board and so on.Because of the current electronic products are constantly small with fine, circuit board can make circuit miniaturization, intuitive, for the batch production of fixed circuit and optimization of electrical layout plays an important role, so the application is more and more widely. The difference between flexible aluminum substrate copper substrate and aluminum substrate :1, the thermal conductivity of copper substrate is twice that of aluminum substrate, the higher the thermal conductivity, the higher the heat conduction obedience, the better the heat dissipation function. 2, copper substrate can be processed into metallized holes, and aluminum substrate can not be flexible aluminum substrate

Aluminum substrate is a kind of metal base copper clad plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are respectively circuit layer (copper foil), insulation layer and metal base. For high-end use, there are also double panels designed for circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A few applications for multilayer board, can be made of ordinary multilayer board and insulation layer, aluminum base bonding. Aluminum substrate and PCB board difference:. 3, copper and aluminum elastic modulus difference is large, so the warpage of copper substrate and the expansion and contraction will be smaller than the aluminum substrate. Copper substrate is one of the most expensive metal substrate, thermal conductivity is many times better than aluminum substrate and iron substrate, suitable for high frequency circuits and high and low temperature change areas and precision communication equipment heat dissipation and architectural decoration industry. LED aluminum substrate is PCB, is also the meaning of printed circuit board, but the material of the circuit board is aluminum alloy, before our general circuit board material is glass fiber, but because the LED heat is larger, so the CIRCUIT board used by LED lamps is generally aluminum substrate, can conduct heat fast, other equipment or electrical circuit board or glass fiber board! Working principle of aluminum substrate: the surface of the power device is mounted on the circuit layer, and the heat generated during the operation of the device is rapidly transmitted to the metal base through the insulation layer, and then the heat is transmitted out by the metal base, so as to realize the heat dissipation of the device

3, steel sheet - hard texture, the same function as FR4, used for welding reinforcement, beautiful than FR4, can be grounded, hardness is higher than FR4; The steel sheet is made of imported stainless steel after heat treatment and fine grinding. It has the advantages of high precision, strong tensile strength, good finish, toughness and not easy to break. Heat dissipation is significantly better than that of standard FR-4 structures. B. The dielectric used is typically 5 to 10 times the thermal conductivity of conventional epoxy glass and 1/10 of the thickness. C. The heat transfer index is more efficient than traditional rigid PCBS. D. You can use copper weights lower than those shown on the IPC recommended chart. Application of aluminum substrate PCB :1. Audio equipment: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier, etc. 2. Power supply equipment: switching voltage regulator, DC/AC converter, SW voltage regulator, etc. 4, TPX film - a high performance high temperature resistant resin blocking release film, used for circuit board pressing process, after special process design, can be used to block resin overflow after the buried hole and blind hole multiple laminating process, with good adhesive resistance, plug hole effect.

Flexible aluminum plate, in recent years, mobile electronic devices such as smartphones, tablets, led by the consumer electronics market growth, manifest the trend of miniaturization, light and flexible aluminum base plate (2) observation is there after high temperature electronic components in the circuit, electrolytic capacitors have not summoned the leakage phenomenon, should be replaced. 2. Annual maintenance :(1) clean up the dust on the circuit board. (2) on the circuit board of electrolytic capacitor capacity sampling, such as found that the capacity of electrolytic capacitor is less than 20% of the nominal capacity, should be replaced, the life of the general electrolytic capacitor should be replaced for ten years or so, to ensure the performance of the circuit board. As a result, traditional PCB has been unable to meet the requirements of the product, so major manufacturers began to study new technologies to replace PCB, and FPC, as the most popular technology, is becoming the main connecting parts of electronic equipment.

Contact: Ms.Huang

Phone: 15023181892(微信同號)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA