I. Definition and classification of FPC manufacturing industry

FPC flexible circuit board, also known as soft printed PCB circuit board, belongs to printed PCB circuit board (PCB), is an important electronic device interconnection component of electronic equipment. FPC flexible circuit board has incomparable advantages of other kinds of PCB, in the current use of electronic equipment, the probability of being replaced is low.

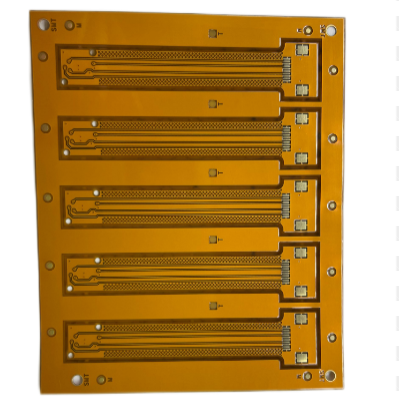

FPC flexible circuit board can be divided into polyimide (PI), polyester (PET) and PEN according to the type of plastic film. Among them, polyimide FPC flexible circuit board is the most common type of soft board, such raw materials with high temperature resistance, good specifications and reliability, and both mechanical equipment maintenance and excellent electrical equipment dielectric strength of the protective film according to the suppression of the final goods.

According to the number of stacking layers, FPC flexible circuit board can be classified into single-sided FPC flexible circuit board, two-layer FPC flexible circuit board and double-layer FPC flexible circuit board. The production technology is based on the production technology of single-sided FPC flexible circuit board, and is maintained according to the lamination technology. Details are as follows:

Second, FPC manufacturing industry development trend analysis report

The upstream and downstream key of flexible circuit board (FPC) is FCLL (flexible copper-clad plate). FCLL key is composed of three kinds of raw materials, that is, insulating layer base film raw material, metal material electric conductor foil and adhesive. At the present stage, the most common materials used for insulating layer base film of flexible copper clad plate are polyester film (PET plastic film) and polyimide film (PI plastic film). Metal material electric conductor foil mainly consists of electrolytic copper (ED) and calendered copper foil (RA), in which calendered copper foil (RA) is the more critical commodity. Adhesives are the key components of double layer flexible coppers, acrylate adhesives and epoxy resin adhesives are more critical commodities.

In 2015, the worldwide sales market of FPC flexible circuit board was about 11.84 billion DOLLARS, accounting for 20.6% of PCB. In 2017, the global PCB value is estimated to reach us $65.7 billion, of which THE annual output value of FPC flexible PCB is US $15.7 billion. It is estimated that the annual output value of FPC flexible circuit board will reach usd 16.5 billion in 2018.

In 2018, China's FPC flexible circuit board production accounted for about half of the world. Data show that in 2018, the production of flexible circuit board (FPC) was 93.072 million square meters, compared with 80.03 million square meters in 2017, up 16.3%.

Iii.FPC manufacturing industry demand analysis report

1. Automobile manufacturing

FPC flexible circuit board because of its flexible, light weight and other characteristics, in recent years as a connecting part is widely used in the CAR ECU (electronic device control module), such as table board display information, speakers, display screen and other equipment with high data signal transmission and high trust requirements, according to the investigation, The amount of FPC used in each car exceeds about 100 pieces.

In 2018, the sales volume of cars around the world reached 95,634,600, with the continuous improvement of the level of intelligent car system. The intelligent living car needs to be equipped with many body controllers and monitors, and the electronic equipment is far more than the general car. From 2012 to 2020, the total number of on-board display configuration will increase by 233%, exceeding the total production of cars in 2020, more than 100 million/year. The import substitution of vehicle display screen, the development trend of engineering and the improvement of total business scale, the total number and quality of FPC for vehicle display screen clearly put forward higher provisions.

2. Smart wearable devices

With the popularity of AR/VR/ wearable sales market around the world, international large and medium-sized electronic product manufacturers such as Google, Microsoft, iPhone, Samsung and SONY are competing to increase their efforts and product research and development. Leading enterprises in China, such as Baidu Search, Tencent, Qihoo 360 and Xiaomi mobile phone, are also competing to rationally layout the smart wearable device industry.

In 2018, the worldwide sales volume of smart wearable devices exceeded 172.15 million units. In the first half of 2019, the sales volume of smart wearable devices reached 83.8 million units. It is estimated that the sales volume of smart wearable devices will exceed 252 million units by 2021. FPC has the characteristics of lightweight and bendable, which is the best choice for connecting components of smart wearable devices. FPC manufacturing industry will become one of the vested interests in the rapid development of smart wearable devices sales market.

FPC manufacturing industry market competition layout analysis

Because China's FPC flexible circuit board manufacturing industry developed too late, with the advantage of the first foreign companies such as Japan Flag win, Japan fujicang, China's Taiwan Zhen Ding, Taiwan County, China and other downstream customers have more closely related business process collaboration, occupy China's FPC sales market dominance. Although the difference between the technology and quality of domestic FPC products and foreign companies is significantly smaller, its production capacity and operation scale is still lagging behind foreign companies, so it is in a weak influence in the competition for middle and downstream medium and large high-quality customers.

With the further improvement of the overall strength of China's local electronic equipment well-known brands, in recent years in China's local FPC flexible circuit board manufacturers make great efforts to reasonable layout of FPC flexible circuit board industry chain.

In order to promote the development trend of intelligent system in China's processing industry, in December 2016, the country implemented the 13th Five-Year Overall Plan for Intelligent Manufacturing System in China, which clearly puts forward that by 2020, the traditional manufacturing industry in China will be updated with intelligence, and in 2025, top priority companies will maintain the transformation and development of intelligent system. Intelligent manufacturing system has become a key driving force for the transformation and development of China's processing industry and the promotion of competitiveness. Especially in the FPC flexible circuit board labor-intensive enterprise transformation and upgrading requirements are great, in China's intelligent manufacturing system manufacturing industry has a broad future.

Contact: Ms.Huang

Phone: 15023181892(微信同號(hào))

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA